In our daily life, we often find some garments with printed patterns. The prints of these garments have certain rules, and they are very symmetrical and beautiful when cut. So how are these materials made? Today, Datu will introduce to you the practical application cases of printed swimsuits.

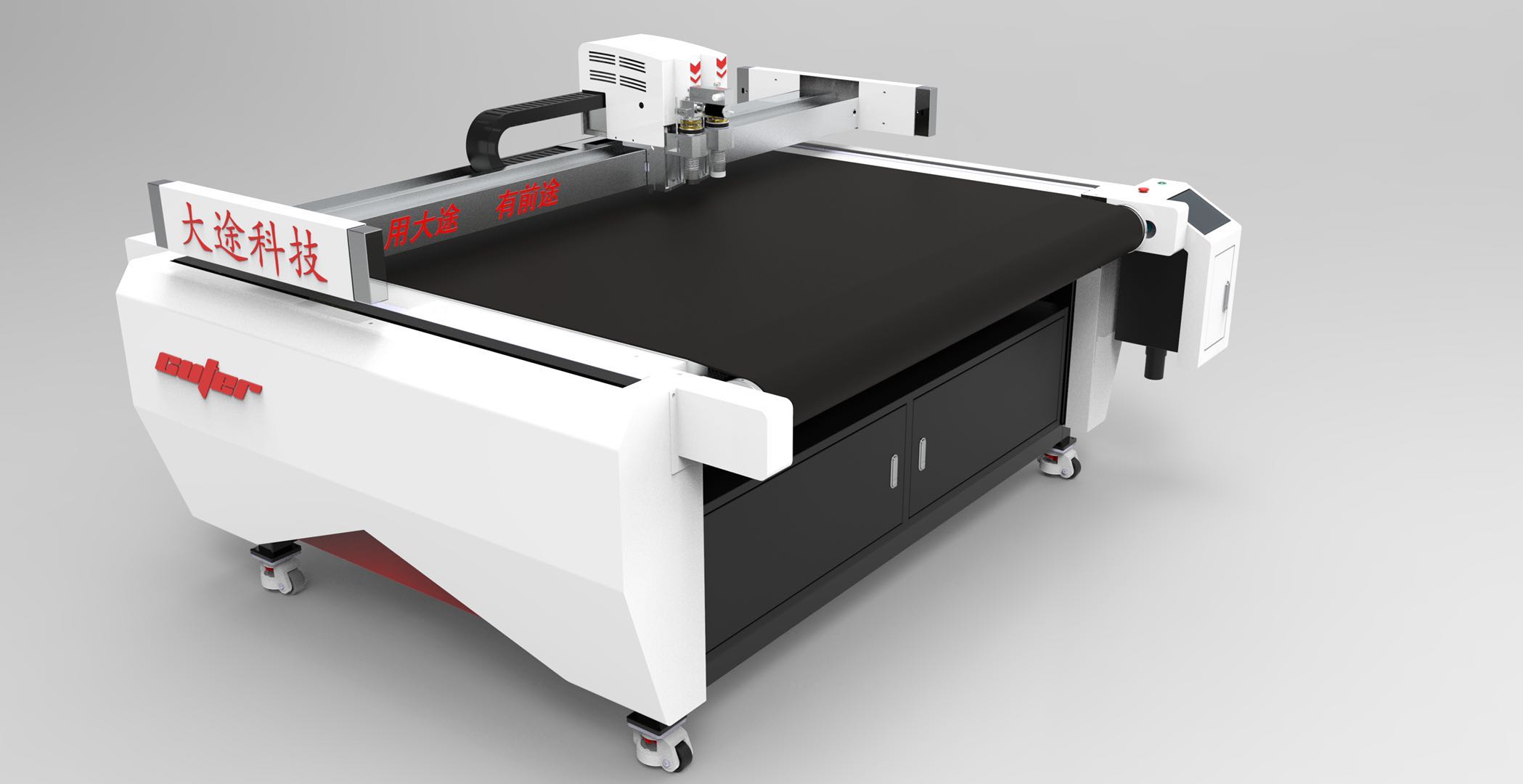

The customer is making printed swimsuit. In the early years, when cutting the cloth with printed pattern, it was mostly artificial cutting, which was inefficient and often needed to work overtime. Besides, compared with efficiency, it was more difficult to control the cutting accuracy. Datu recommended vibration knife cutting machine with printing recognition function for customers.

Printing recognition cutting machine is to install a camera on the top of the vibrating knife cutting machine. When the printing cloth is laid flat on the table surface, the top camera starts to take photos, the computer recognizes the photos, extracts the printing part in the photos, and the equipment automatically cuts according to the extracted outline after the extraction is completed.

Generally speaking, the printed swimsuit cutting machine has the following four advantages:

1. Fully automatic cutting replaces labor. The equipment integrates automatic feeding, contour extraction, cutting and unloading, which is enough to replace 4-6 manual workers.

2. High efficiency, the equipment adopts imported Mitsubishi servo system, cooperates with the self-developed cutting system, the running speed can reach 2000mm/s, and the cutting speed is between 200-1500mm/s.

3. The cutting precision is high. The equipment adopts the pulse positioning system, and the positioning precision is ±0.01mm. The cutting precision should be calculated according to the elasticity of the material. Clothing fabrics can generally be controlled at about 0.5mm.

4. Saving materials , the equipment not only supports the cutting of printing materials, but also supports the automatic cutting of common materials, and the equipment has an automatic typesetting function. Compared with manual typesetting, the equipment saves more than 15% of materials.

Post time: Jun-05-2023