The use of vibrating knife cutting machine for leather goods, sofas, curtains and other flexible material enterprises cutting and cutting can liberate the labor force, while improving environmental protection, greatly improve production efficiency. However, customers may face various problems when using, such as: cannot operate, equipment failure and so on. If the strength of the manufacturer is relatively poor, the after-sales service provided is imperfect, etc., it will be very troublesome and affect production.

And Datu technology as a deep cultivation of the field of vibration knife more than 10 years of enterprises, always put the quality of equipment and brand reputation in the first place, vibration knife cutting machine configuration generally use better performance of imported or well-known brands, in the field of after-sales,Datu technology all members are required to actively respond to customer problems, and timely solution.

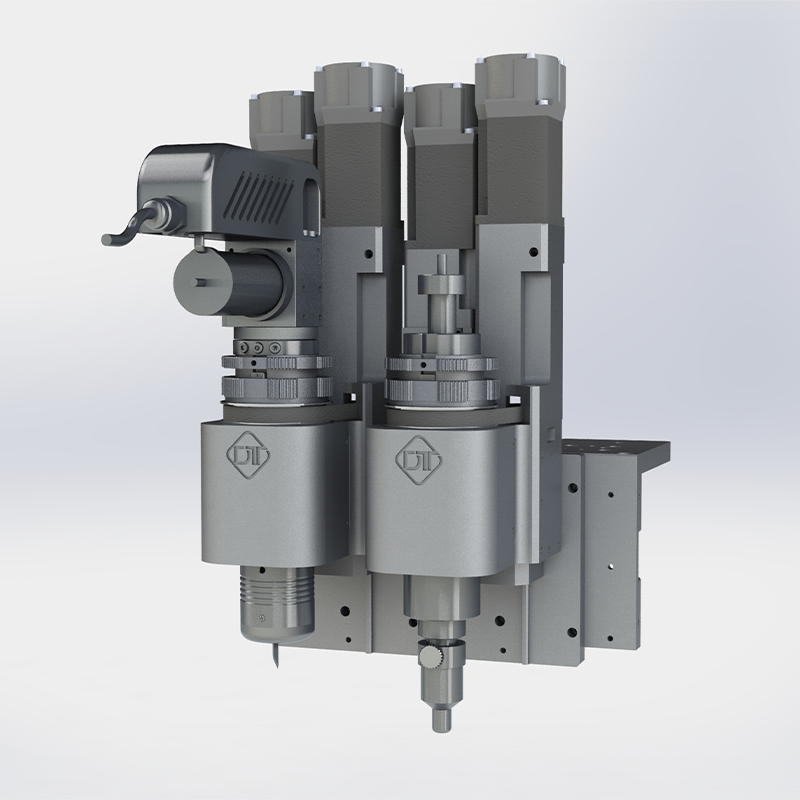

Vibrating knife cutting machine tool can not fall and rise normally, how to do?

Fault analysis:

1. The fabric is too sticky and the cutting thickness is too high;

2. Sensor or line fault causes;

3. The cylinder and gas pipe are faulty;

4. The lifting and lowering of the tool holder may collide with the whetstone or other related parts;

5. The tool holder lifting rod and linear bearing are too oily;

6. The upper and lower limit column or shock absorber is loose;

Solution:

1. For fabrics with large viscosity, the thickness of the cut fabric should be reduced;

2. Check whether the sensor and the related line head of the upper and lower cylinder of the tool are J20 joints;

3. Check the line of the upper and lower solenoid valve of the tool and the flow regulating valve of the gas pipe;

4. Check whether the knife holder meets the whetstone or other relevant parts when lifting;

5. Timely clean up excessive oil pollution at the tool holder lifting rod and linear bearing;

6. Check whether the lifting position of the knife holder is normal, and adjust the lifting position of the knife holder appropriately.

Post time: Nov-24-2023