For the flexible material cutting industry, the vibrating knife cutting machine has already become the preferred cutting equipment, on the one hand because of the fast and efficient characteristics of the vibrating knife cutting machine, and on the other hand because it has a very wide range of applications.

At present, the scope of application of the vibrating knife cutting machine has covered more than 95% of the flexible material cutting industry, including leather, automotive interiors, carpet floor mats, clothing fabrics, silicone gaskets, carton packaging, home fabrics, etc. With a good application, and achieved a very good cutting effect.

But no matter what industry it is used in, the precision of cutting is very important. Whether it is a cutting machine, a blanking machine or a special-shaped cutting equipment, the precision of the finished product has long become an important criterion for judging the quality of a cutting machine. Today, I will tell you about the factors that affect the cutting accuracy of the cutting machine.

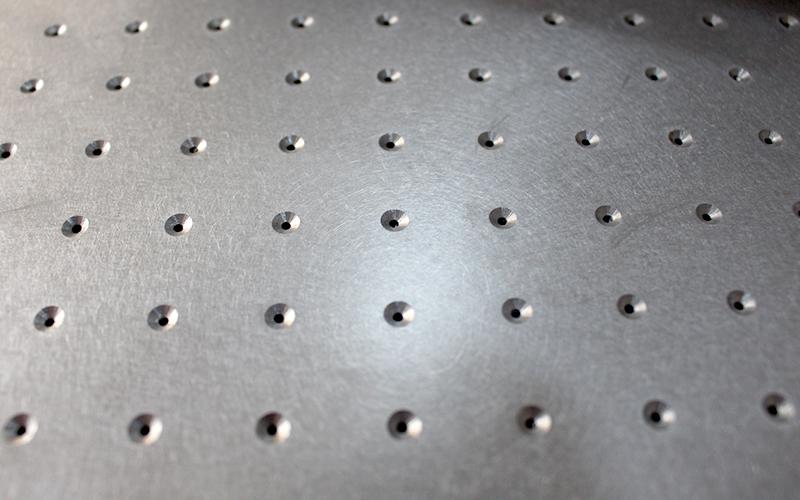

1. Working table

The work surface will affect the cutting accuracy to a large extent. If the work surface is not flat, it will not only cut continuously, but also the size will be inaccurate.

Such cutting products will increase unnecessary work, and the material cannot be reworked continuously, and the waste is very serious.

2.the blade

The main point here is the degree of wear resistance of the blade. The blade that has just left the factory is very sharp regardless of whether the material is good or bad. The key is how long this sharpness can be maintained. This requires users to make comparisons in the subsequent production process.

The blade cannot be cheap, and the blade itself is not expensive. The most expensive blade is only tens of dollars. If the cutting accuracy is reduced in order to save dozens of dollars, it will affect the quality of the product.

And a good blade can not only improve the cutting accuracy, but also promote the cutting speed.

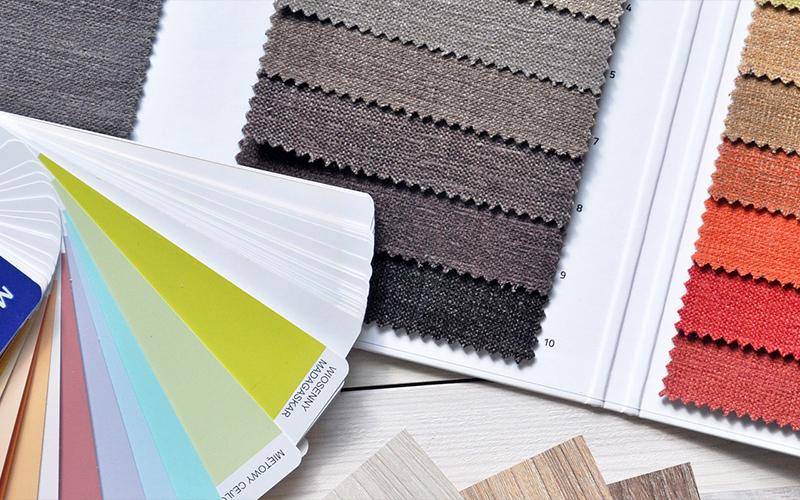

3. The material to be cut

The accuracy of the cutting machine is not only affected by its own parameters, but also has different cutting accuracy for different materials. For example, under the same conditions and parameters, the final accuracy of cutting cloth and cutting soft glass will definitely be different. This is because the hardness, flexibility, and thickness of the material are jointly affected.

Our vibrating knife cutting machine can freely change the tool head,when cutting different materials, the appropriate tool head should be replaced according to the characteristics of the material, so that the cutting quality is better, improve the competitiveness of the product.

Post time: Oct-19-2022