Vibrating knife cutting machine in principle from 1984 began production, is developed by the well-known Swiss brand ZUND, its equipment name is cutting machine, and then introduced into the country, domestic manufacturers gradually create their own cutting equipment, because it is the use of blade vibration cutting, gradually called vibrating knife cutting machine.

The domestic vibrating knife cutting machine has a big gap with foreign countries, but the domestic first-line brands are gradually moving closer to foreign countries, in this article we will focus on the domestic vibrating knife cutting machine, about its working principle.

Vibrating knife cutting machine can also be called computer cutting machine, the knife has a round knife, pneumatic knife, oblique cutting, slotting, punching and other tools, are all for cutting services, so the vibrating knife cutting machine can be said to be a type of equipment, different tool working mode is different.

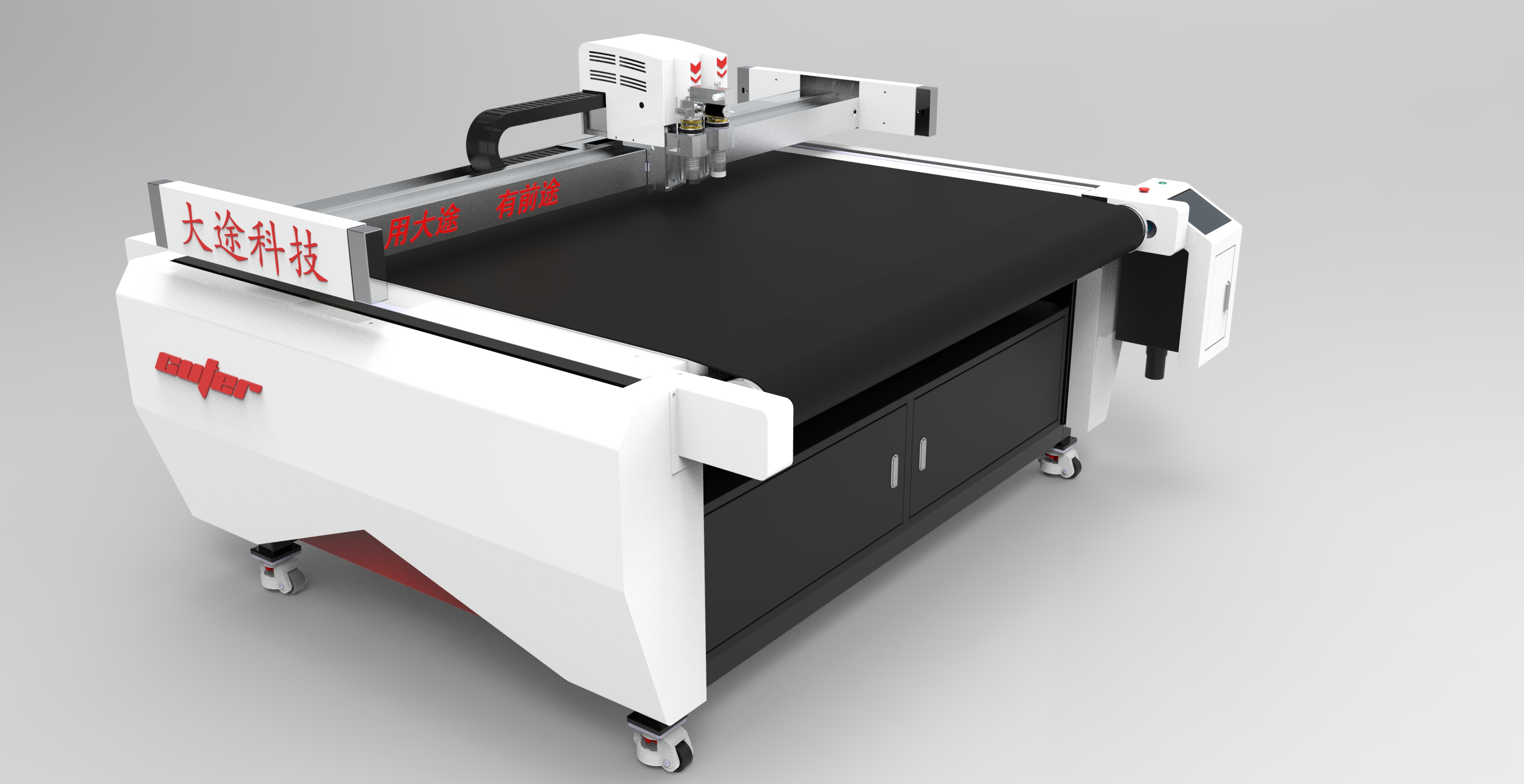

The whole equipment is composed of operating system, electrical appliance, bed, workbench, sheet metal, gantry, feeding frame and cutting tool. The working mode of the Datu cutting machine:

1. First place the material on the automatic feeding rack.

2, the computer input version type, start automatic typesetting.

3, equipment automatically pull material, identify material location.

4, the blade work begins to cut.

5, after the cutting is completed, the material begins to automatically unloading.

The equipment uses blade cutting, the cutting process does not produce smoke, but also because of kinetic energy cutting, the thickness and hardness of the material have a great impact on the cutting speed and cutting effect of the equipment. The larger the amplitude, the stronger the kinetic energy, the better the cutting effect and speed .

Vibrating knife is the use of motor to drive the blade reciprocating motion, suitable for leather, thick cloth and other support adsorption of thick materials cutting.

Round knife is blade self-rotating cutting, suitable for cutting materials with good permeability.

The pneumatic knife uses an air source to drive the blade to cut, and the kinetic energy of the air source is larger than that of the motor, so the thickness of the cutting is thicker.

Post time: Oct-25-2023