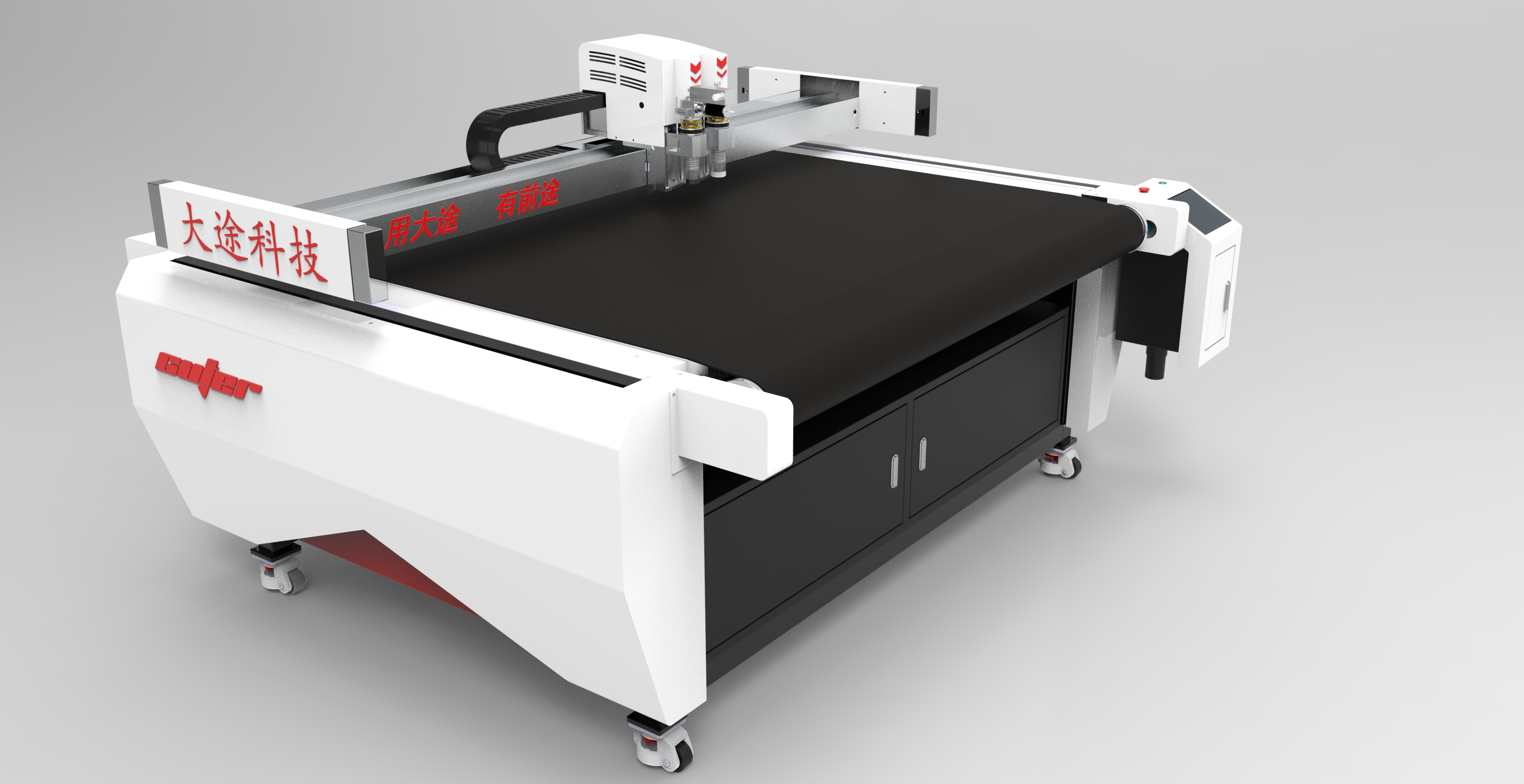

Silicone mat cutting machine is a computer-controlled cutting equipment, automatic cutting, replacing 4-6 manual, equipment set automatic feeding, cutting, slotting, unloading and so on as one, to help manufacturers reduce costs and increase efficiency.

The automatic feeding device of the silicone mat cutting machine is for the coil feeding, according to the company’s previous experience, the silicone mat material used for the sealing gasket does not need an automatic feeding device, and can be directly ordered on the equipment.

Automatic feeding is completed after the cutting and grooving steps, this step is the main working part of the silicone mat cutting machine, silicone mat cutting machine has a round knife, pneumatic knife, vibration knife, grooving, miter cutting and other tools, respectively for the material, hardness, process of different materials.

Silicone mat cutting machine in general has three major advantages:

The first material saving, the equipment has automatic typesetting function, compared with manual typesetting can save more than 15% of materials.

The second process is controllable, we all know that people are the most difficult to manage, and the standardization of equipment can make the management more controllable, so the production cost will be far lower than the labor production cost.

Third, high efficiency, equipment efficiency and accuracy double high, equipment idling operation efficiency 2000mm/s, this value and the thickness of the material and hardness is related, the interval value is generally 200-1200mm/s, the equipment uses pulse positioning, positioning accuracy ±0.01mm.

Post time: Jul-27-2023