PVC film is already one of the irreplaceable common materials, and it is developing rapidly and has broad prospects. All countries are optimistic about the potential of PVC and its benefits to the ecological environment.

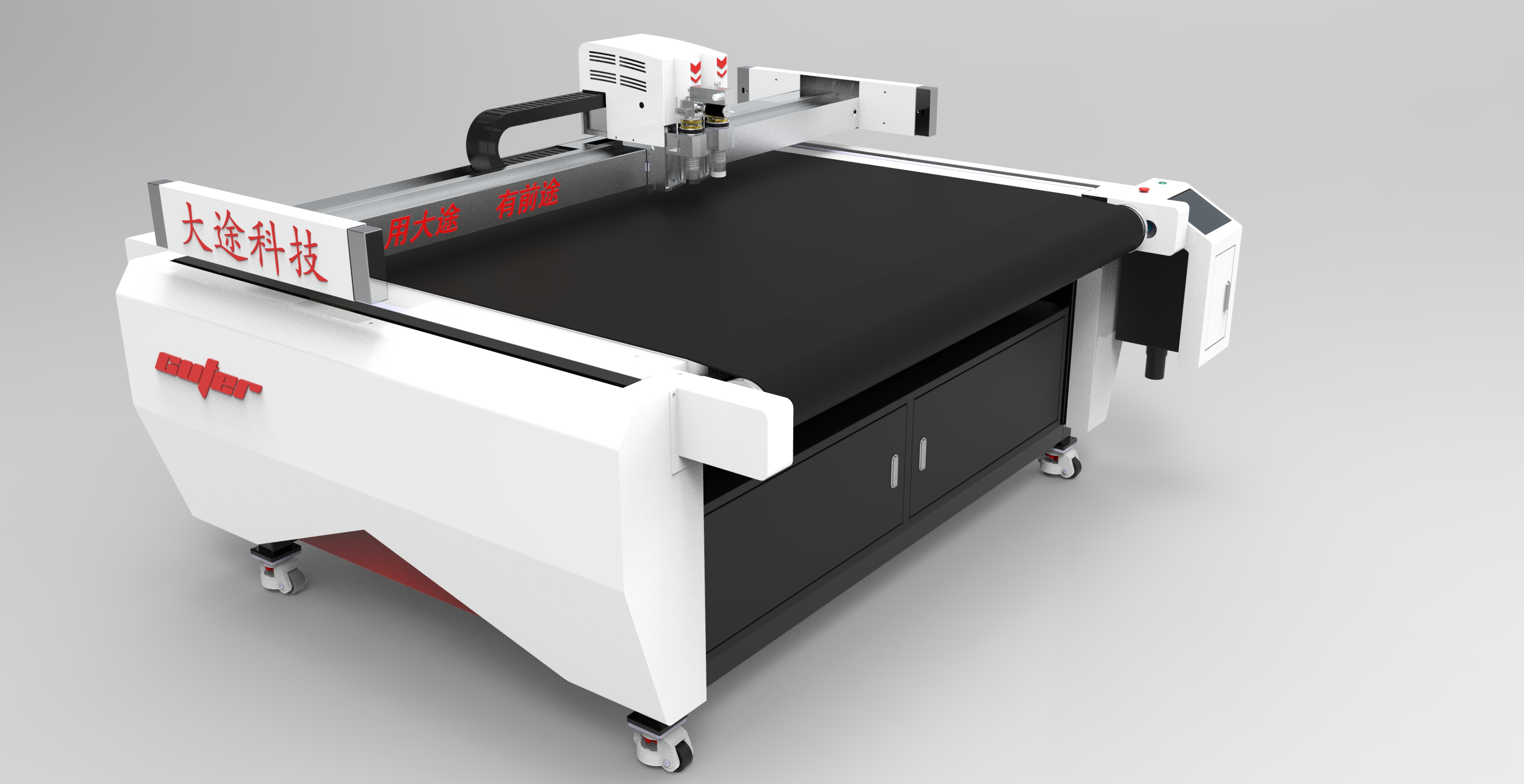

PVC film cutting is an important part of processing. There are laser cutting and blade cutting for PVC film cutting. Due to the nature of PVC film, laser cutting will generate a lot of smoke and cause environmental pollution. Therefore, Datu Intelligent Technology Co., Ltd. recommends oscillating knife pvc film cutting machine.

Vibrating knife pvc film cutting machine focuses on intelligent and environmentally friendly cutting, conforming to the development of the times, pvc film cutting is operated by computer numerical control, intelligent cutting system independently developed by Datu, and multi-axis control system independently developed to realize automatic feeding of flexible materials such as plates and coils , cutting, and unloading. The specific cutting process is: first design the shape to be cut in the computer and start automatic typesetting. After the typesetting is completed, put the material on the feeding rack and start the equipment to automatically cut. The cutting process is very simple, and one person can complete the operation independently.

Advantages of vibrating knife pvc film cutting machine:

1. Environmentally friendly cutting, cutting without pollution and emission.

2. High efficiency, vibrating knife cutting machine can replace 4-6 workers

3. High precision, the cutting precision of the vibrating knife cutting machine is controlled at ±0.01mm.

Post time: Apr-14-2023