Snow boots originated in Australia, and are popular among consumers because of their strong breathability, warmth and cold resistance, and comfort, and they are popular all over the world.

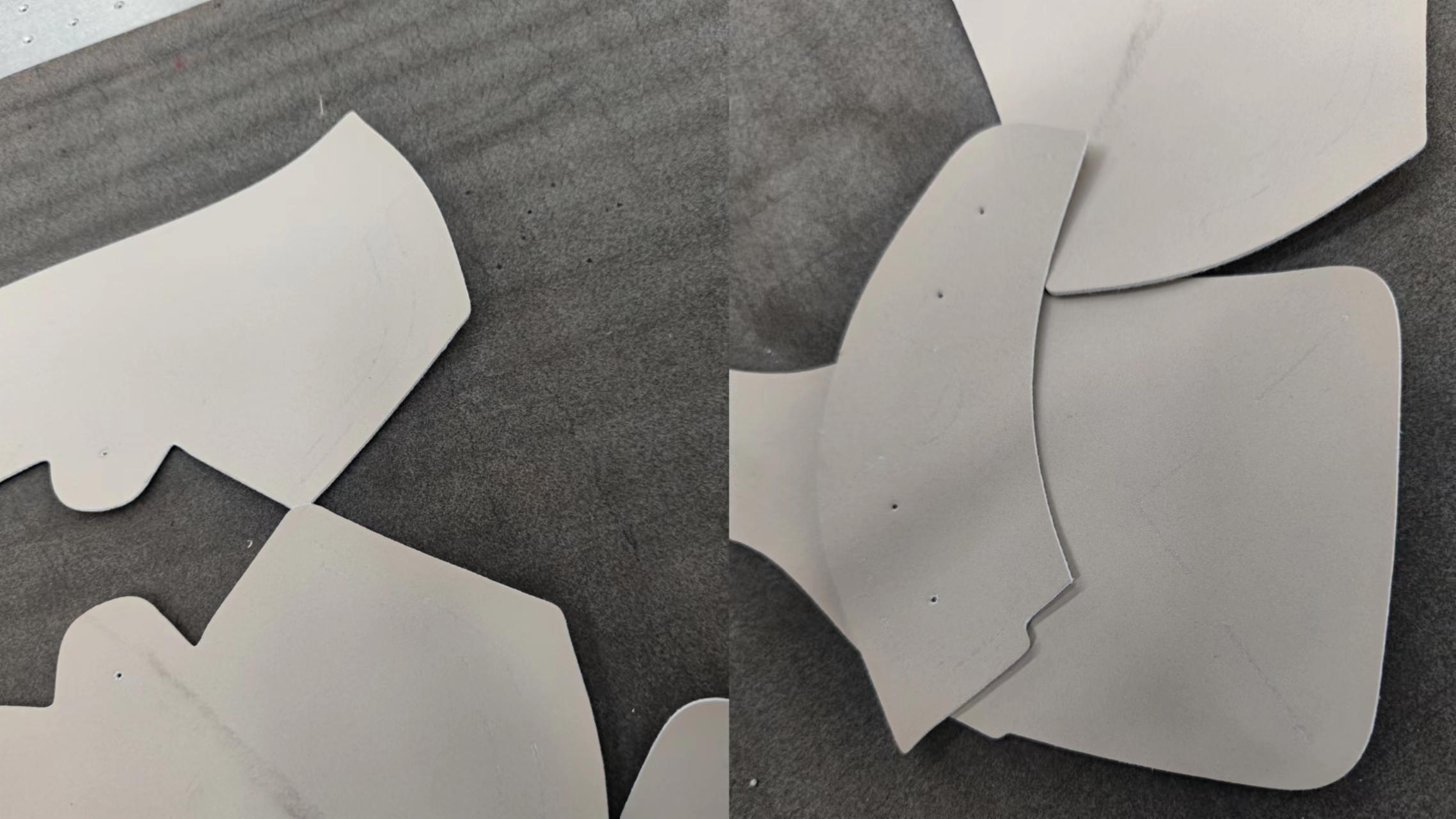

The production method of snow boots is generally divided into the following steps: shoe pattern plate making – cutting shoe pattern – sewing upper – making sole – sewing the upper and sole with needle and thread.

High-quality snow boots are made of whole lambskin or selected cowhide made in Australia with Australian wool, and the soles also have a special structure. Even the cost of our domestic fur materials is not a small expense. There are inevitably some waste problems in manual cutting, and the utilization rate of fabrics is low. On the one hand, manual typesetting wastes time, and on the other hand, manual labor cannot fully utilize the fabric. Sometimes the wrong version is cut due to human error.

Datu snow boot cutting machine can be equipped with vibrating knife, round knife, pneumatic knife and other types of cutter heads to meet the cutting needs of different materials. Input the type of shoe sample to be made into the computer, and the computer will automatically make a compact layout of the shoe sample, with a utilization rate of more than 90%. After typesetting, the machine automatically cuts, and the manual only needs to operate the machine. In addition, the machine can not only cut the shoes of snow boots, but also other sports shoes, leather shoes and sandals.

Post time: Sep-23-2022